-

Product DescriptionCompany Info.<>

- Processing customization:

- Yes

- Model:

- KER

- Alias:

- high-temperature push-plate kiln

- Applicable scope:

- general

- Maximum furnace temperature:

- 700 ℃

- Operating temperature:

- 600 ℃

- Loading capacity:

- 1 kg

- Studio size:

- Width 370mm high 150mm mm

- Overall dimension:

- 14500*4000*2.200mm mm

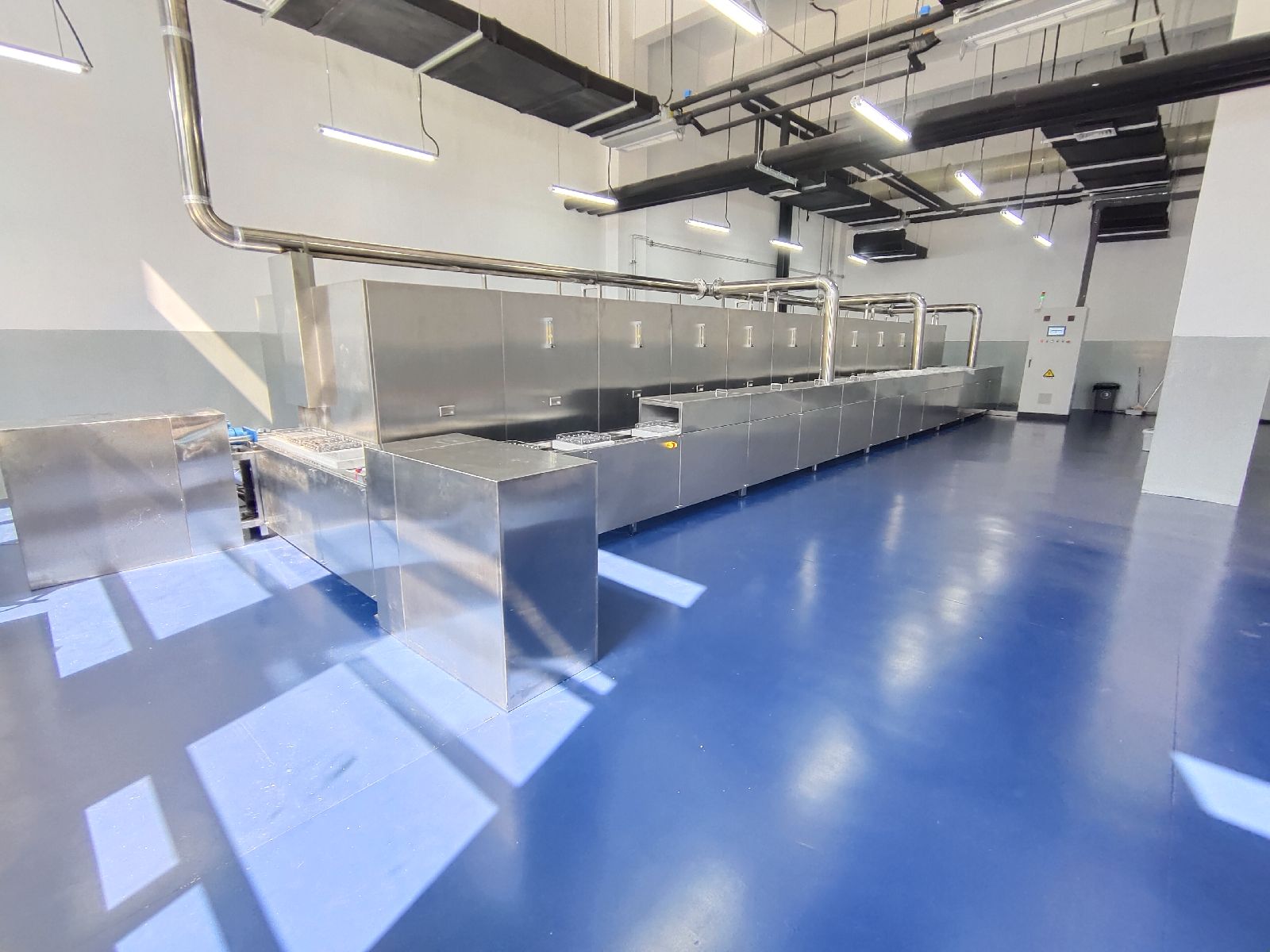

device name

High temperature carbon removal equipment for microwave pusher kiln

host appearance size length, width and height

14000X4000X1800mm

Distance between independent electric control cabinet and equipment

1500mm

Equipment internal width

350mm

Height of equipment support frame

1800mm

mains input

AC380+/-10%V

mains frequency

50HZ

microwave total power

130KW

Transformer cooling mode

oil immersed water cooled

equipment noise

≤70dB

Heating outside the cavity during operation

≤50℃

surface temperature

60℃-70℃

ambient temperature requirement

0-40℃

Equipment Theme Material

GB 304 stainless steel

Use maintenance size length, width and height

16000X6000X2500mm

Equipment control mode

PLC Automation

Internal height of heating section

150mm

suppressor opening height

150mm

microwave frequency

2450MHZ+/-50MHZ

Magnetron cooling method

water-cooled

Internal temperature of electric control cabinet during operation

≤50℃

Outside the electrical box during operation

≤70℃

apparent power

150KVA

Environmental humidity requirements

≤80℃

Contact material part saggar

quartz crucible

microwave leakage value

≤2mw/c ㎡(in line with 2mw/c ㎡ national jia standard)

use environment

No flammable, explosive or corrosive gases

Capacity/day

50*24=1200kg

Origin of use

Hebei (Province)

apply

carborundum

Microwave sintering is a method of sintering materials using microwave heating. Microwave sintering technology is a kind of method that utilizes the kinetic energy and thermal energy of the internal molecules absorbed by the material to heat the whole material uniformly to a certain temperature and realize densification sintering. It is an important technical means to rapidly prepare new materials with high quality and traditional materials with new properties. Compared with the conventional sintering method, microwave sintering has the advantages of rapid heating, low sintering temperature, fine structure, improved material properties, no pollution and high efficiency and energy saving, so it is called a new generation sintering method.

Compared with the traditional sintering technology, the microwave sintering technology has higher density, hardness and toughness. Short sintering time produces uniform fine-grained microstructure with few internal pores, which are round in shape than conventionally sintered, resulting in better ductility and toughness. Because microwaves have great penetration into most powder ceramic materials, they can heat the workpiece evenly, reduce the temperature gradient in the high temperature sintering process, thereby reducing the deformation of the material caused by uneven expansion, making it possible to quickly heat up, and the time of residence at high temperature can be greatly shortened, inhibiting the growth of grains and improving the physical and mechanical properties of the material.

- Name(chinese)

- Name(English)

- Henan Keer Microwave Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Zhoukou City, Henan, China

- Nearby port

- Dalian,Yingkou,Qinhuangdao,Tangshan,Tianjin,Qingdao,Yantai,Rizhao,Nantong,Suzhou,Nanjing,Zhenjiang,Lianyungang,Shanghai,Ningbo,Zhoushan,Wenzhou,Fuzhou,Xiamen,Shantou,Shenzhen,Guangzhou,Zhuhai,Zhanjiang,Haikou,Fangcheng

Henan Keer Microwave Technology Co., Ltd. is a high-tech enterprise integrating scientific research, production and trade. In December 2009, our company's "Industrial Microwave Energy Equipment" was approved and recognized as a high-tech product, and our company was also rated as "Zhoukou City Private Science and Technology Enterprise." The company is committed to the promotion of new energy represented by microwave energy, especially applications in microwave drying, microwave heating, microwave sterilization and microwave chemistry. Microwave sources with magnetron as the core and microwave anti-leakage structures as the core. System design of door body and opening. The company consists of a R & D team of engineers who have been engaged in technical work in the electromagnetic and microwave fields for many years. Through advanced microwave CAD technology, the company uses finite element method to guide the design of microwave systems to ensure good matching of microwave source, waveguide, and resonant cavity systems, and achieve true efficiency. Energy saving. In today's society, energy is becoming increasingly tight, while market cost competition is becoming increasingly fierce. The company hopes that through the "efficient new energy" provided by us, we will enable customers to reduce production energy consumption, improve production efficiency and product quality in industries such as the food industry, wood products industry, rubber products industry, ceramic industry, chemical industry, pharmaceutical industry, agricultural product processing, garbage and sewage treatment. In line with the pragmatic entrepreneurial spirit of "promotion, support, practice, and win-win", the young Kohl personnel rely on their strong technical strength, complete testing methods, scientific management, and excellent quality assurance system to ensure true "excellent quality, customer first". On the basis of jointly conducting application experiments according to the user's product quality and process requirements before production, a careful design is made, specific implementation plans are proposed, and the user's consensus is obtained and then precision manufacturing is carried out. Responsible for product installation, debugging and training; implement the service promise of one-year warranty and lifelong technical support. Thank you for your support and trust in us. We will serve you wholeheartedly!- Name(chinese)

- Name(English)

- Henan Keer Microwave Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Zhoukou City, Henan, China

- Nearby port

- Dalian,Yingkou,Qinhuangdao,Tangshan,Tianjin,Qingdao,Yantai,Rizhao,Nantong,Suzhou,Nanjing,Zhenjiang,Lianyungang,Shanghai,Ningbo,Zhoushan,Wenzhou,Fuzhou,Xiamen,Shantou,Shenzhen,Guangzhou,Zhuhai,Zhanjiang,Haikou,Fangcheng

Henan Keer Microwave Technology Co., Ltd. is a high-tech enterprise integrating scientific research, production and trade. In December 2009, our company's "Industrial Microwave Energy Equipment" was approved and recognized as a high-tech product, and our company was also rated as "Zhoukou City Private Science and Technology Enterprise." The company is committed to the promotion of new energy represented by microwave energy, especially applications in microwave drying, microwave heating, microwave sterilization and microwave chemistry. Microwave sources with magnetron as the core and microwave anti-leakage structures as the core. System design of door body and opening. The company consists of a R & D team of engineers who have been engaged in technical work in the electromagnetic and microwave fields for many years. Through advanced microwave CAD technology, the company uses finite element method to guide the design of microwave systems to ensure good matching of microwave source, waveguide, and resonant cavity systems, and achieve true efficiency. Energy saving. In today's society, energy is becoming increasingly tight, while market cost competition is becoming increasingly fierce. The company hopes that through the "efficient new energy" provided by us, we will enable customers to reduce production energy consumption, improve production efficiency and product quality in industries such as the food industry, wood products industry, rubber products industry, ceramic industry, chemical industry, pharmaceutical industry, agricultural product processing, garbage and sewage treatment. In line with the pragmatic entrepreneurial spirit of "promotion, support, practice, and win-win", the young Kohl personnel rely on their strong technical strength, complete testing methods, scientific management, and excellent quality assurance system to ensure true "excellent quality, customer first". On the basis of jointly conducting application experiments according to the user's product quality and process requirements before production, a careful design is made, specific implementation plans are proposed, and the user's consensus is obtained and then precision manufacturing is carried out. Responsible for product installation, debugging and training; implement the service promise of one-year warranty and lifelong technical support. Thank you for your support and trust in us. We will serve you wholeheartedly! -

Send your message to this supplier*From:*To:

Miss. an

*Message:

Miss. an

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.