-

Product DescriptionCompany Info.<>

- Processing customization:

- Yes

- Model:

- KER-SJ-75KW

- Alias:

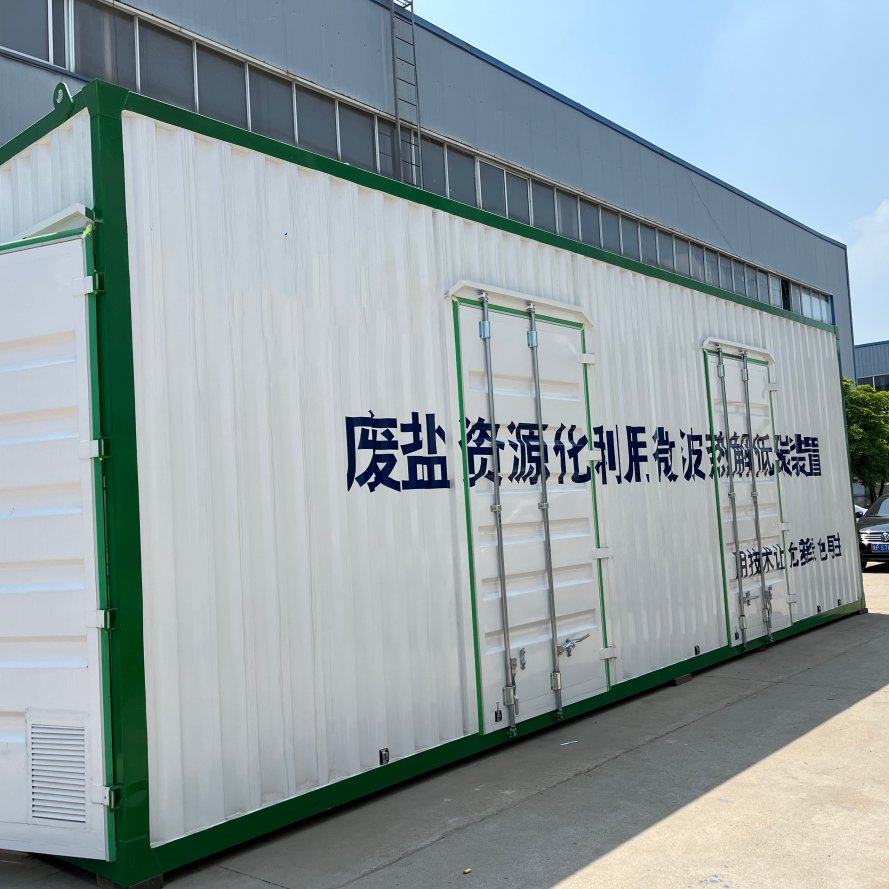

- Microwave pyrolysis of waste salt

- Applicable scope:

- Microwave pyrolysis of carbon black

- Maximum furnace temperature:

- 1000 ℃

- Operating temperature:

- 600-1000 ℃

- Studio size:

- 0-40 mm

- Overall dimension:

- Length 10m * width 3.5m* height 3.3m mm

Pyrolysis of waste tires solves thedanger and harm caused by waste tire accumulation. Combustible gas, oil and pyrolytic carbon black can be recovered from waste tires by pyrolysis. Pyrolytic carbon black is the key product of tire pyrolysis, and its quality and market application restrict the economy of pyrolysis recovery process of waste tires. Therefore, how to improve the performance of pyrolytic carbon black, enhance its use value, and scientifically characterize the performance of pyrolytic carbon black is an important link in the comprehensive utilization of waste tire resources.

name

detailed

device name

Microwave thermal analysis system for waste salt

Equipment size

Length 10m * Width 3.5m* Height 3.3m

installation (unit) weight

10t

rated power

75KW

microwave frequency

2.45GHz±25MH

operating temperature

600-1000℃

equipment noise

≤85dB (sound pressure level), measured according to JB/T8098-1999 standard

container surface temperature

≤50℃

main material

304 stainless steel

Site Use Space

Length 15m* Width 8m* Height 4m

site requirements

Hardened, smooth

mains input

AC380+/-10%V(≥100kW)

mains frequency

50HZ

phase

three-phase electricity

equipment production

140kg/H

control system

PLC operation

Environmental humidity requirements

≤80℃

ambient temperature requirement

0~40℃

use environment

No flammable, explosive or corrosive gases

equipment material

Box and shell are 304 stainless steel processing

temperature measurement accuracy

±1°C

Magnetron life is

Not less than 5000 hours or 300 days, whichever is shorter

Origin of use

Chongqing City

applicable product

Waste salt pyrolysis

equipment characteristic

1 mobile integrated equipment: microwave oven body and control system self-contained, fixed on the mobile frame, cao for convenient, flexible movement, small footprint.

2 Microwave output power adjustable, high temperature: microwave frequency: 2.45GHz 25MHz; continuous working temperature: 1000℃.

3 with atmosphere protection function: equipment can be operated in natural air, can also meet the atmosphere of protective gas sintering.

4 temperature detection ce wide range: thermocouple temperature measurement device, real-time detection ce temperature range 0~1000 C.

5 quartz glass furnace can rotate when the equipment is in use, the rotation speed can be adjusted, and the quartz furnace angle can be adjusted when loading and unloading.

6 Simple cooling water system: The equipment is equipped with a standard circulating cooling water system, users do not need to be equipped with cooling water system, installation, debugging is simple, easy to use.

7 Microwave energy feed-in matching is good: 1.5kW industrial microwave source is used, the oven cavity is cylindrical, the microwave forms diffuse reflection in the oven cavity, the microwave field in the oven cavity is uniform, and the material will not produce hot spots when sintering.

8cao strong operability, easy to use: PLC+ touch screen control mode, touch screen for its own interface, U disk can be inserted into the touch screen, equipment operation data automatically stored in the U disk, through the PC can be directly edited and printed U disk data; can set a number of temperature control curves, with automatic sintering and manual sintering dual functions; can be selected according to the specific conditions of the experiment single magnetron or multi-tube working mode, to avoid magnetron long-term in low power or high power working state, damage magnetron.

9an is fully reliable: equipped with industrial-grade water-cooled microwave source system, which can be used continuously for 24 hours; special microwave shielding sealing ring is adopted to shield microwave leakage between oven body and oven cover; microwave leakage value of equipment system is far lower than that of guo family standard, microwave leakage is 0.2mw/cm2, which is only equivalent to the radiation level when using mobile phone. It comes with microwave anti-leakage alarm device and an all-lock, and microwave source can be automatically or manually cut off when microwave exceeds standard.

10 High temperature resistant and anti-corrosion materials: The furnace tube is made of quartz glass tube, the furnace body is made of 304 stainless steel, and the frame is made of carbon steel paint.

- Name(chinese)

- Name(English)

- Henan Keer Microwave Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Zhoukou City, Henan, China

- Nearby port

- Dalian,Yingkou,Qinhuangdao,Tangshan,Tianjin,Qingdao,Yantai,Rizhao,Nantong,Suzhou,Nanjing,Zhenjiang,Lianyungang,Shanghai,Ningbo,Zhoushan,Wenzhou,Fuzhou,Xiamen,Shantou,Shenzhen,Guangzhou,Zhuhai,Zhanjiang,Haikou,Fangcheng

Henan Keer Microwave Technology Co., Ltd. is a high-tech enterprise integrating scientific research, production and trade. In December 2009, our company's "Industrial Microwave Energy Equipment" was approved and recognized as a high-tech product, and our company was also rated as "Zhoukou City Private Science and Technology Enterprise." The company is committed to the promotion of new energy represented by microwave energy, especially applications in microwave drying, microwave heating, microwave sterilization and microwave chemistry. Microwave sources with magnetron as the core and microwave anti-leakage structures as the core. System design of door body and opening. The company consists of a R & D team of engineers who have been engaged in technical work in the electromagnetic and microwave fields for many years. Through advanced microwave CAD technology, the company uses finite element method to guide the design of microwave systems to ensure good matching of microwave source, waveguide, and resonant cavity systems, and achieve true efficiency. Energy saving. In today's society, energy is becoming increasingly tight, while market cost competition is becoming increasingly fierce. The company hopes that through the "efficient new energy" provided by us, we will enable customers to reduce production energy consumption, improve production efficiency and product quality in industries such as the food industry, wood products industry, rubber products industry, ceramic industry, chemical industry, pharmaceutical industry, agricultural product processing, garbage and sewage treatment. In line with the pragmatic entrepreneurial spirit of "promotion, support, practice, and win-win", the young Kohl personnel rely on their strong technical strength, complete testing methods, scientific management, and excellent quality assurance system to ensure true "excellent quality, customer first". On the basis of jointly conducting application experiments according to the user's product quality and process requirements before production, a careful design is made, specific implementation plans are proposed, and the user's consensus is obtained and then precision manufacturing is carried out. Responsible for product installation, debugging and training; implement the service promise of one-year warranty and lifelong technical support. Thank you for your support and trust in us. We will serve you wholeheartedly!- Name(chinese)

- Name(English)

- Henan Keer Microwave Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Zhoukou City, Henan, China

- Nearby port

- Dalian,Yingkou,Qinhuangdao,Tangshan,Tianjin,Qingdao,Yantai,Rizhao,Nantong,Suzhou,Nanjing,Zhenjiang,Lianyungang,Shanghai,Ningbo,Zhoushan,Wenzhou,Fuzhou,Xiamen,Shantou,Shenzhen,Guangzhou,Zhuhai,Zhanjiang,Haikou,Fangcheng

Henan Keer Microwave Technology Co., Ltd. is a high-tech enterprise integrating scientific research, production and trade. In December 2009, our company's "Industrial Microwave Energy Equipment" was approved and recognized as a high-tech product, and our company was also rated as "Zhoukou City Private Science and Technology Enterprise." The company is committed to the promotion of new energy represented by microwave energy, especially applications in microwave drying, microwave heating, microwave sterilization and microwave chemistry. Microwave sources with magnetron as the core and microwave anti-leakage structures as the core. System design of door body and opening. The company consists of a R & D team of engineers who have been engaged in technical work in the electromagnetic and microwave fields for many years. Through advanced microwave CAD technology, the company uses finite element method to guide the design of microwave systems to ensure good matching of microwave source, waveguide, and resonant cavity systems, and achieve true efficiency. Energy saving. In today's society, energy is becoming increasingly tight, while market cost competition is becoming increasingly fierce. The company hopes that through the "efficient new energy" provided by us, we will enable customers to reduce production energy consumption, improve production efficiency and product quality in industries such as the food industry, wood products industry, rubber products industry, ceramic industry, chemical industry, pharmaceutical industry, agricultural product processing, garbage and sewage treatment. In line with the pragmatic entrepreneurial spirit of "promotion, support, practice, and win-win", the young Kohl personnel rely on their strong technical strength, complete testing methods, scientific management, and excellent quality assurance system to ensure true "excellent quality, customer first". On the basis of jointly conducting application experiments according to the user's product quality and process requirements before production, a careful design is made, specific implementation plans are proposed, and the user's consensus is obtained and then precision manufacturing is carried out. Responsible for product installation, debugging and training; implement the service promise of one-year warranty and lifelong technical support. Thank you for your support and trust in us. We will serve you wholeheartedly! -

Send your message to this supplier*From:*To:

Miss. an

*Message:

Miss. an

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.